THE PACKAGING OF OUR PRODUCTS

We want to be transparent with you. Choosing the right packaging is not simple because several criteria come into play: CO2 emission, renewable raw material or exhaustible, its ability to be recycled and/or reused, and its ability to generate waste which will degrade more or less quickly, but also its price.

We have not always been perfect, we have not always opted for the right materials, that's for sure. However, we wanted to find a solution to this. Our company is growing and we wanted to ask ourselves a fundamental question when more than 5500 orders are sent from our offices per year.

What is the packaging that pollutes the least?

Just between us, any packaging pollutes and that (for now) is irreversible. However, we can reduce our impact with a few simple actions, that's for sure.

After changing the packaging several times, we think we have found which one that is the most durable one.

We had several options to choose from:

Kraft packaging

Plastic packaging

Biogodegradable plastic packaging

Bio-based plastic packaging

Returnable packaging

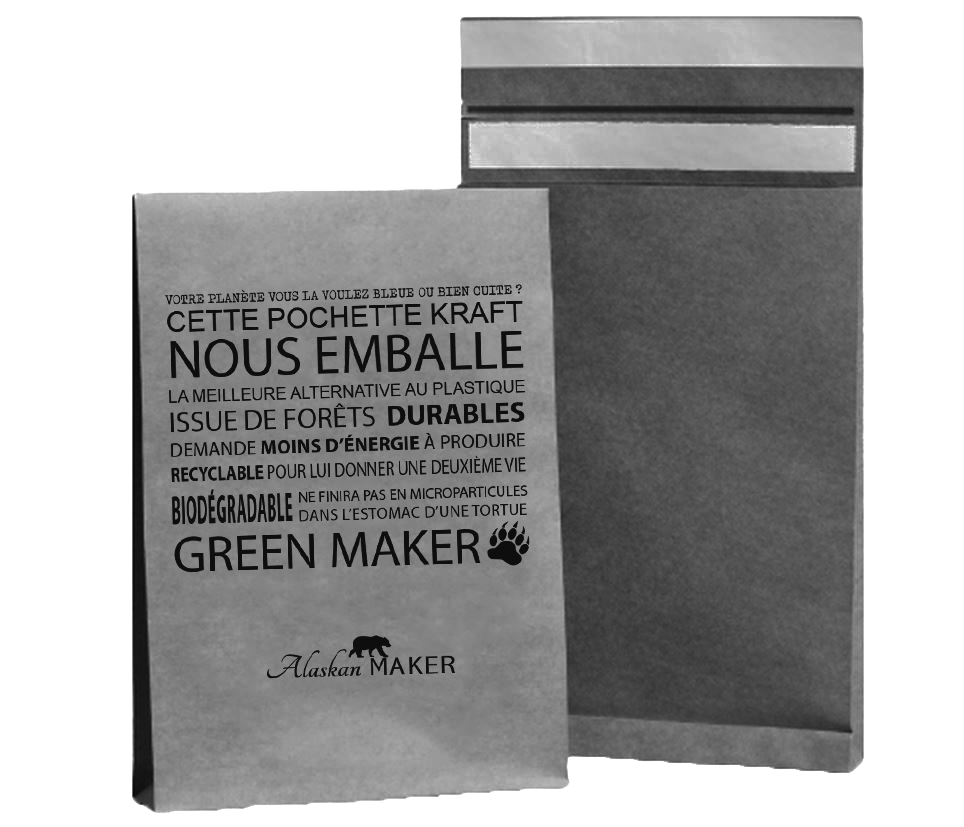

KRAFT Packaging

This is the one we chose and we will explain why. To make these pouches, trees are selected, peeled, washed and then cut to be transformed into fine wood chips. These wood chips are then transformed into dried pulp and compressed using steel rolls into Kraft packaging. After completing its packing job, it has 3 options:

▪️ Being cremated (8% of production)

▪️ Being buried (12%) for a degradation of the cardboard which will last between 6 months and 1 year.

▪️ Or being recycled (80%), meaning that the cardboard can be reused 10 times.

The production of cardboard causes greenhouse gas emissions like any packaging production. However, our Kraft packaging is FSC certified, meaning that the kraft comes from sustainable forests*. These forests sequester CO2 which makes it possible to offset emissions during production and recycling. In the end, for 100gr of cardboard, 12gr of CO2 equivalent on average were emitted. In terms of emission we do not do better for other packaging and you will see why. This packaging is the best option we have found for shipping our products to you. Of course you can also find them at our various resellers but contrary to what one might think it is more ecological to order on the internet than to go shopping, mainly because of your means of travel to get to the shop. If you go there on a scooter, it's already better! We also want to be careful to avoid excess packaging, neither internal nor external in your packages, we only put what is necessary. According to the cardboard specialist DS Smith, 43% of the content in protective packaging is vacuum. It is therefore obvious to reduce this waste as much as possible!

Plastic Packaging

We have obviously all once ordered on the internet and received our long awaited product in a beautiful and immaculate white pocket. This plastic sleeve, it must be said, did not get very good press. When we know that plastics placed in landfill can end up in the oceans, that's not great. This plastic pouch is made of low density polyethylene (LDPE, HDPE). Plastic is made from petroleum, an exhaustible resource unlike trees from FSC forests. Then the production of plastic emits 2090kg/ton of CO2 equivalent. At the end of their life, that is to say after their only use, these pockets are: ▪️ Either recycled which corresponds to 10% of what has produced and which releases 18kg kg/ton of CO2 equivalent. ▪️ Either they are buried in the ground and it will take 450 years for them to are degrading (that's still a hell of a year) and this generates 33 kg/ton of CO2 equivalent. 58% of the production is incinerated . ▪️ Last option, 32% of the plastic is incinerated which releases 2914 kg/ton of CO2 equivalent which is nevertheless compensated by the energy created by the incineration. In short: its asset is that it is not expensive but it is really the only one!

Biogodegradable plastic packaging

The packaging is a “biodegradable” plastic. We put it in quotes because it's a bit more complex than that. This packaging has the same origin as traditional plastic: petroleum, an exhaustible resource. However, after its extraction additives are added so that the plastic degrades more quickly. Thanks to these additives, its degradation goes from 450 years to 4 years. Not bad, is it? Well yes but that is not enough, because it emits as many greenhouse gases as conventional plastic during its production and at the end of its cycle. Like conventional plastic, the pouches are either: ▪️ 58% buried. ▪️ Incinerated at 32% ▪️ And the rest cannot be composted by individuals because they can only be composted in an industrial composter, there is no sector in France for particular for this kind of plastic called "biodegradable". And yes, because for plastic to degrade faster you need a temperature of over 70 °C, a humidity of 70% and an oxygen level of 20% . Not so easy to degrade in the end... So, like conventional packaging, it releases as many greenhouse gases while degrading, despite everything more quickly.

Bio-based plastic packaging

This time the packaging is in bioplastic , ie it is biodegradable and bio-based , otherwise called PLA for polylactic acid. Unlike the two previous packages, the raw material is renewable , often sugar cane or corn. This plant material sequesters C02 to compensate for its emission during production, which makes its emission relatively neutral . But once again this is not enough because for waste management it is once again complicated. At the end of its life, like plastic, they are: ▪️ 58% buried ▪ 32% incinerated ▪️ Unfortunately the rest cannot be composted by individuals because once again the conditions for its decomposition are too complicated for individuals in the same way than biodegradable plastic. In addition, PLA releases toxic substances during composting . So that's better, but it's not yet a solution.

Returnable reusable packaging

The returnable packaging is an innovation of the last few years. Many companies have opted for this upcycling option. A great initiative to limit single-use packaging. Thanks to a deposit system the packaging is returned to the sender via a factory for checking and can also be refurbished if it has been damaged. On paper, it divides the impact of a package by the number of times it has been shipped. On the other hand, in these cases, it is also necessary to take into account the different journeys made by these boxes to be returned to the verification plant and to the sender. It is also necessary to have a consideration of price, which is not negligible, because the price of this packaging would be more expensive for the customer .

*Bioplastic: Biobased and/or biodegradable plastic.

*FSC: "FSC's mission is to promote responsible management of the world's forests - that is, management that is environmentally appropriate, socially beneficial and economically viable, to meet the needs of present and future generations." sources : https://fr.fsc.org/fr-fr https://www.bilans-ges.ademe.fr/